Being a solar thermal technology provider, TVP Solar SA will help SPIRIT study how high temperature heat pumps (HTHPs) can best utilise solar heat as the source for carbon-free heat upgrade applications in the process industry.

TVP will explore alternative approaches and concepts for the integration of solar thermal with SPIRIT HTHPs and will contribute to the development of relevant business models.

Also, TVP will elaborate on replication cases to show how heat pumps and solar thermal systems can be combined for sustainable heat generation. These replication cases will allow extending the operating range of industrial heat pumps and thus their market potential.

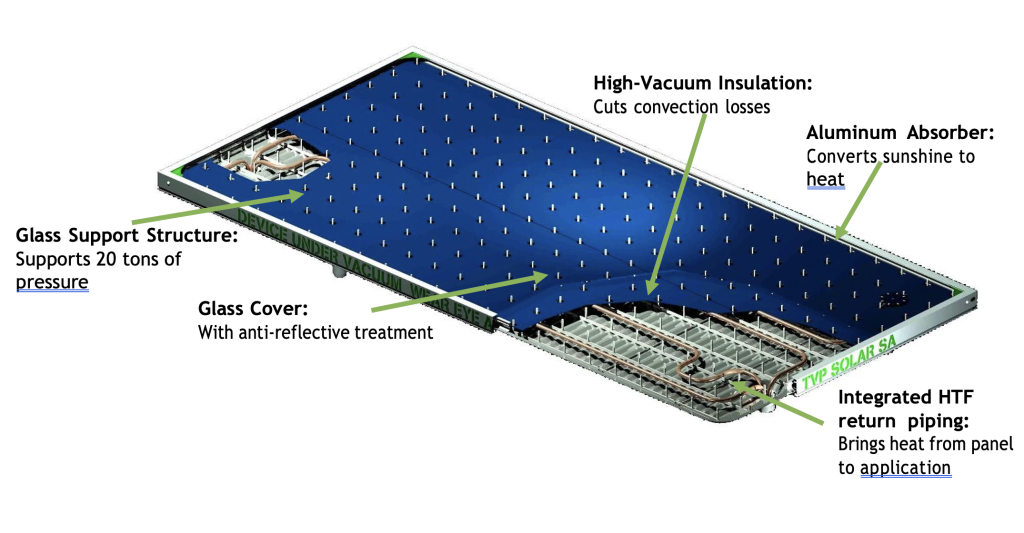

The High Vacuum Flat Panel

The High Vacuum Flat Panel (HVFP) is a non-concentrated solar thermal technology that uniquely combines a flat design under high vacuum. The technology has been developed, has been certified and is owned by TVP Solar SA, which manufactures and markets HVFPs under the ‘MT-Power’ brand name.

The company has engineered, installed and commissioned HVFP-based solar thermal systems for industrial-scale applications in 9 countries around Europe, Middle East and Americas.

Main Components of TVP’s HVFP solar collector

Why has this type of technology been chosen?

The MT-Power HVFP is a high-end SolarKeyMark-certified product that generates heat up to 200°C for industrial-scale solar thermal applications exhibiting solar-to-heat conversion efficiencies up to 65% at 80°C and 45% at 180°C.

Thanks to this high-vacuum technology and flat design, MT-Power panels exhibit minimal thermal losses, no degradation over time, and thus exceptional efficiency throughout their extended lifetime.

Without need of cleaning and with only minimal maintenance, TVP’s nearly 100% recyclable solar collectors can operate for 25 years to substitute fossil fuels and deliver emission-free thermal energy across climates and geographies all around the world and throughout the year. HVFP-based systems produce heat cheaper than gaseous and liquid fossil fuels.

Based on the above characteristics HVFPs comprise a suitable candidate for operational coupling with industrial heat pumps at medium temperature heat upgrade applications.

HVFP-based system for industrial process heat in Turin, northern Italy

Integrating Solar Thermal and High Temperature Heat Pumps

SPIRIT has identified five integration strategies for Solar Thermal (ST) and High Temperature Heat Pumps (HT HPs):

- Complementary Heat Source: Solar thermal supplements waste heat streams for heat pump operation

- Winter Heat Upgrade: Heat pumps upgrade solar heat during low-irradiance periods

- Extended Operation: Heat pumps utilize stored solar heat beyond daylight hours

- Combined Sources: Solar heat increases waste heat temperature, improving the COP of the HP

- Seasonal Operation: Direct solar process heat in summer, heat pump integration in winter

The optimal solution of ST and HT HP integration depends on parameters such as the heat demand profile, the availability or not of waste heat, the location of the industrial consumer, the HP technology, etc.

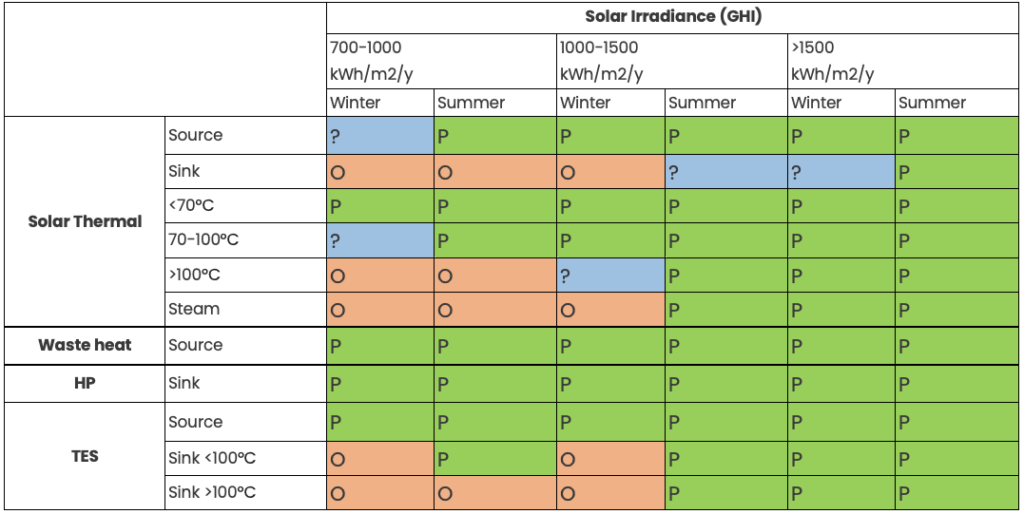

In general, the following options may be considered depending on the location – solar irradiance; solar heat may be used as a heat source for a HT HP, may directly serve industrial heat demand (sink) by producing hot water or even low-pressure steam as shown in the table below:

This table indicates potential uses of a heat upgrade systems based on solar thermal and HP integration.

As an example, a location with solar irradiance (GHI) of 1’100kWh/m2/year, may use an integrated solution combining ST (as heat source <100°C), WH (heat source), HP (heat sink) and TES (heat source <100°C) during both winter and summer time. At the same location, generation of solar heat >100 °C may not be feasible during the winter period.

Similarly, the use of solar heat directly for the process requirements may be possible in places with GHI > 1500 kWh/m2/year. Still at these locations, integration with a HT HP and TES could help extending the operating hours of the system beyond daytime or during low irradiance hours.

Solar Thermal Capabilities for Industrial Heat Supply

The SPIRIT project has recently carried out a comprehensive analysis of solar thermal integration scenarios across European industrial sites. The analysis has demonstrated the capability of TVP Solar’s High Vacuum Flat Panel (HVFP) technology of meeting the demand of industrial heat applications in various European locations and operating scenarios.

TVP Solar’s patented high vacuum technology enables SolarKeyMark certified performance up to 200°C with minimal thermal losses over 20+ year lifespan.

For each of the three demo-sites of the SPIRIT project, a set of energetic simulations has been performed. An indicative size of peak power around 1 MWth has been considered. This corresponds to roughly 1,600m² panels, which require a total installation area of 3’000m². Different operating scenarios show how solar-to-heat conversion efficiency varies with operating temperature.

Case 1: Norway (Stella Polaris): Low Solar Irradiance Scenarios

Global Horizonta Irradiance (GHI) at the location: 752 kWh/m²/year – Europe’s most challenging solar conditions

- Scenario 1 (solar heat: Tin:23°C – Tout:53°C): 564 kWh/m²/year; 58% efficiency; 170 tons CO₂ savings

- Scenario 2 (23-63°C): 549 kWh/m²/year; 57% efficiency; 170 tnCO₂ savings

- Scenario 3 (83-93°C): 388 kWh/m²/year; 40% efficiency; 126 tnCO₂ savings

Key Finding: Even in extreme northern conditions, solar thermal remains viable for seasonal industrial applications (March-September operation).

Case 2: Czech Republic (Smurfit Kappa): Medium Solar Conditions

GHI at the location: 1,111 kWh/m²/year

- Winter Operation (75-95°C): 607 kWh/m²/year; 47% efficiency; 192 tnCO₂ savings

- High-Temperature Summer (125-135°C): 418 kWh/m²/year; 32% efficiency for steam generation; 148 tnCO₂ savings

Challenge: Solar steam generation

Case 3: Belgium (Tiense Suiker): Dual purpose solar heat:for industrial processes and district heating

GHI at the location: 1,060 kWh/m²/year

- Scenario 1 (81-91°C): 564 kWh/m²/year; 46% efficiency; 178 tnCO₂ savings

- Scenario 2 (81-101°C): 545 kWh/m²/year; 44% efficiency; 175 tnCO₂ savings

Challenge: Seasonal mismatch between solar availability and sugar production cycle requiring innovative storage or symbiosis solutions.